Ladder Safety

Live Broadcast – Daily TBT

This video was filmed a couple of years ago in a live broadcast. We discussed over 20 pieces of advice on ladder safety and had a short Q&A session with the viewers.

What is a ladder?

A ladder is a form of access used to travel from one point to another (mostly vertically). A ladder should not be our first choice to perform work at height tasks. We should use other forms of access that are more secure and stable (scaffolding for example.

What are the tips we covered in this video?

We covered more than 20 tips and they were all kind of linked and merged together. I have broken down some of the tips we discussed in the list below.

1- Don’t use a ladder

This is always my first advice. I always tend to ask the crew if they can do the job another way without the need to use a ladder. If they absolutely must use it, then we will allow them.

2- Use a more stable form of access

Using a scaffold is a lot safer than using ladders. Scaffolds can hold more weight and have guard rails whereas ladders (mostly) don’t.

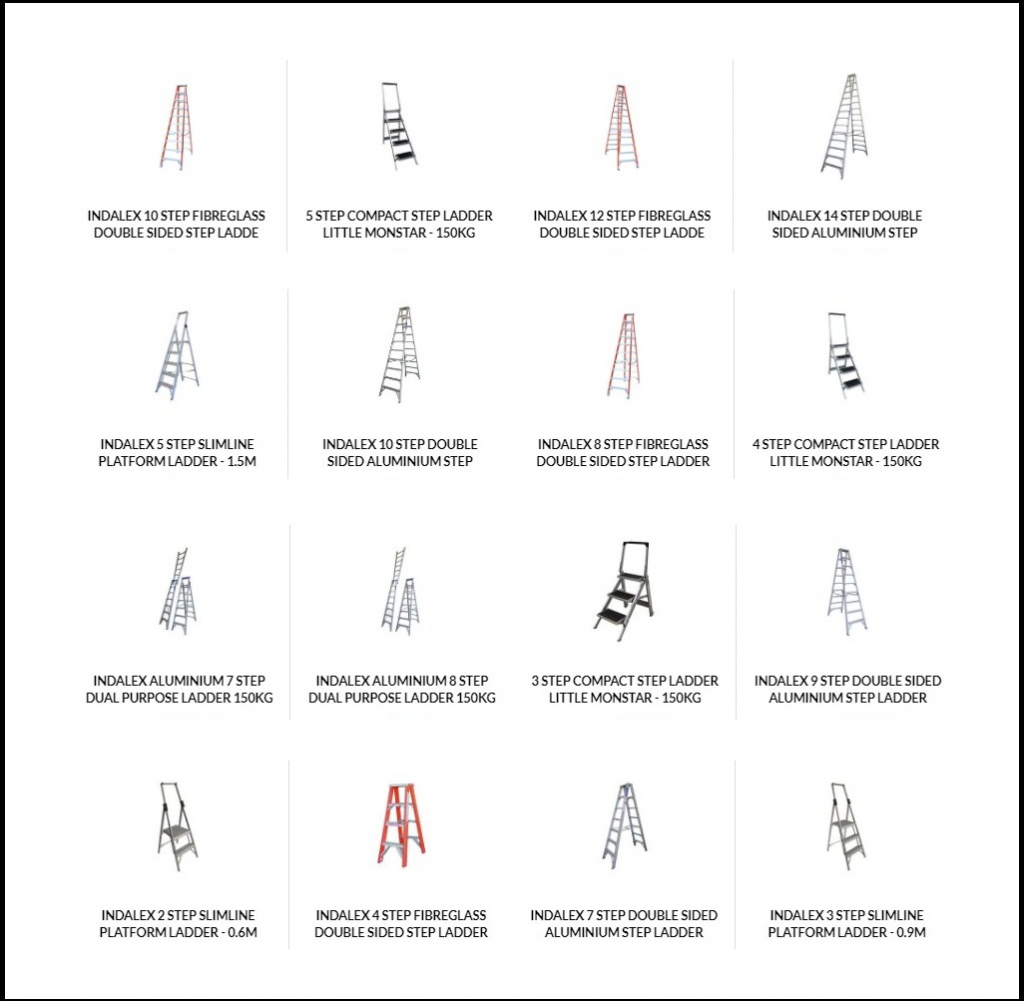

3- Choose the correct ladder

There are a number of ladders out there that you can choose from and it is the responsibility of your employer to provide the right ones for the tasks in your workplace. The video discusses the types of ladders and gives some good examples.

4- Only use ladders that were manufactured by a factory

The ladders we use at work must fit certain standards. We cannot use anything that is given to us by employers and ”Make it Work” one more thing to remember is to ”NEVER USE HOMEMADE LADDERS”

5- Ladder inspection

Now that you’ve chosen a ladder to do your job, it is important that you perform a thorough inspection on it before you use it. The video covers some important points on this but here is a ladder inspection template for you to use.

6- Never Attempt to fix broken ladders

Just like in the simple ladder inspection form from the above link, there can be a number of things wrong with the ladder. It is important to remember your role and not engage in fixing broken, damaged, defective, or painted ladders. You must always follow your company’s policy and procedure in discarding broken equipment and not using them

7- Only trained personnel can use ladders

While it appears very simple, it is not allowed for everyone to work at height (including on ladders) unless they have been trained to do so. A number of factors can prevent a person from working at height and these things must be known before selection.

8- Choosing the best location for the ladder

Placing the ladder on uneven, slippery, or sloppy ground can contribute to an accident taking place, especially if it’s being used by an untrained person. Choose the proper location for the ladder and make sure it is not in the line of fire.

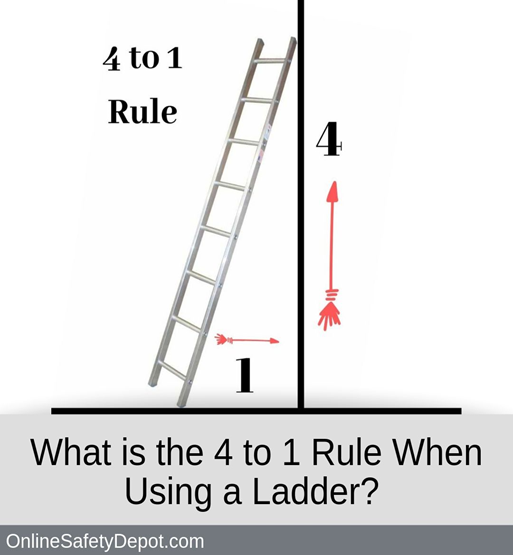

Once that is done, you must remember the 4:1 rule when setting up a ladder. This applies to straight and extension ladders. For every 4 meters the ladder is going up, 1 meter has to be away from the wall. So, if it’s an 8-meter ladder, 2 meters must be considered.

DO NOT USE THE TOP 3 RUNGS.

9- Securing the ladder from the bottom and the top

The ladder must be secured from the top and the bottom. As long as the ladder is free from the top, someone must be holding it from below until it is secured from above. When choosing someone to hold the ladder, make sure that that person is also trained on how to hold the ladder and knows not to stand in the line of fire

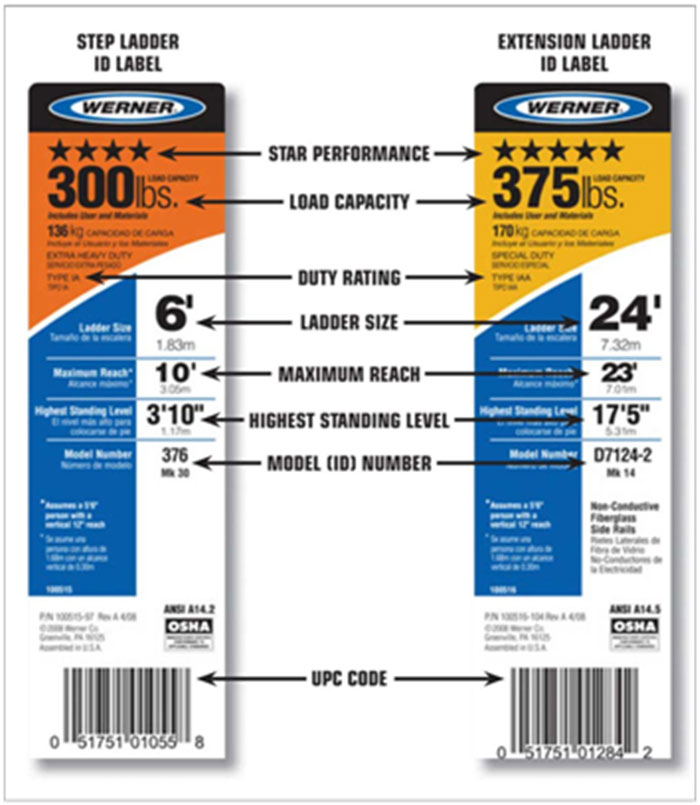

10- Duty Rating – Weight Limit

Another reason why we must only use manufactured ladders from factories is the weight limit. This is normally explained by a sticker on the sides of the ladder or on one of its steps. Your company must have its own procedure to file the ladders and keep a record of them all (for the purpose of inspections and other reasons). Each ladder must be sorted by its duty rating, length, type, brand, and its conductive or non-conductive feature.

NEVER HAVE MORE THAN 1 PERSON ON THE LADDER AT THE SAME TIME

11- (3) points of contact

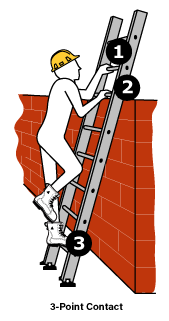

The 3 points of contact rule is very important. You must always have 2 hands and one foot on the ladder or two feet and 1 hand (While climbing). This is to ensure that you are as safe as you can be.

This also means that you must not have any items in your hand(s) while climbing. Having something in your hands will cause you to not have a good grip on the ladder so, leave them empty while climbing.

3-points of contact

12- Tool Belts

There are a number of tool belts available in the market (depending on where you are). Choosing the right kind of belts or straps will help your employees perform their tasks a lot safer than usual and reduce the number of incidents, accidents, and near-misses.

Tool Belt

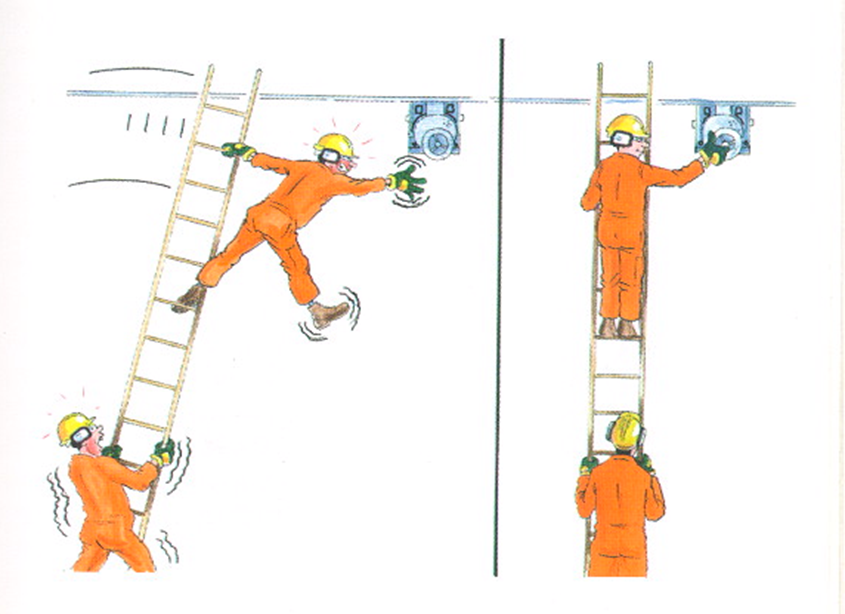

13- Do not over-reach

I remember seeing workers over-reaching in almost every workplace. Over-reaching is when a worker attempts to reach a point that is farther than his horizontal or vertical limit. There are two solutions for this issue:

1- Change the ladder to a longer one so you can reach where you need to be safely without over-reaching, or

2- Climb down, and reposition the ladder closer to where you want to reach

(horizontally), and continue your work.

Over-reaching can easily cause a ladder to slip and take you down with it. Depending on how high you are and what you’ll fall on will determine what your injuries will be.

14- Overhead hazards

Overhead Hazards

The primary hazard to be worried about is electricity and where you stand from its cable (your distance) and the type of ladder and equipment you’re using to do your job. Other than that, you have to consider other operations that are taking place below or above your location.

Another thing is to know if there are any Mobile Elivated Work Platforms (MEWPs) in your work area and if they’ll do any work near you.

The Video

Here is the video we’ve been waiting for all this time but I hope you enjoyed reading the article. A lot of time and effort was put into it and I hope it was worth it.